Application and present situation of virtual Reality technology in manufacturing industry -- Dr. Liu Yun

2021-08-03

Abstract: With the acceleration of China's manufacturing industry transformation and upgrading, different heavy and light industrial products have increasingly high requirements for design, such as the lowest manufacturing cost, the best structure, the best performance and so on. In this design development requirements, through the introduction of CAD, CAE technology and VR space interaction technology, complete the design and optimization of the product structure, do the prediction of the overall process of production and processing, as well as the final three-dimensional display of virtual product space, so as to improve the core competitiveness of products.

Key words: manufacturing industry upgrading virtual reality core competitiveness

1 concept of virtual reality technology

Virtual reality (VR) technology is a multi-field science and technology, human-computer interaction, computer graphics theory, computer technology, etc., combined to create a virtual world, real-time effect. VR technology is based on the theory of human-computer interaction. People can directly observe the world and objects around them, and naturally interact with objects in the virtual world.

2. Technical characteristics of virtual reality technology

VR technology is interactive, immersive, multi-sensory and imaginative.

1) Interactivity. In a simulation environment, the degree to which the user can respond and control the object is interactivity. With the necessary controls, users of the virtual environment can get the same reaction as in the real world, using multi-dimensional information and various types of sensors to interact.

2) Immersion. Also known as telepresence, the use of computers to construct realistic unreal worlds. The user sees and hears in a three-dimensional virtual world just like the real one.

3) Multisensory. In the virtual environment, there is not only the general visual sense, but also the impact of hearing, touch, even smell and taste.

4) Conceivability. Compared with the past, virtual reality technology involves more fields and means, and has a wider space for imagination. It not only restores the real environment, but also has an environment for innovative imagination, even an environment that cannot be reached by existing technologies.

3. Development status of virtual reality technology in manufacturing industry

3.1 Development status abroad

For a long time, as the global manufacturing industry more and more fierce market competition, the enterprise in order to quickly grab market in many countries, continuously revolve around how to improve product quality, improve production efficiency and control production cost, in the 1990 s, as a new manufacturing mode and concept of virtual manufacturing, through continuous development, Has become an important development technology in modern manufacturing technology. In many developed countries, virtual manufacturing technology has been widely used in various fields, including transportation, logistics, manufacturing and so on. For example, the design, assembly, testing and other manufacturing processes of Boeing 777 are all completed based on virtual manufacturing technology. With the support of virtual manufacturing technology, the original 8-year development cycle is shortened to 5 years, improving production efficiency. In addition, virtual manufacturing technology also has a profound impact on the future development of the world manufacturing industry.

3.2 Domestic development status

For a long time, the application of virtual reality technology in various fields in China is not high, but with China's frequent promulgations of relevant support policies, and virtual reality technology is listed as one of the key tasks of future development, reflecting China's attention to the development of virtual reality technology. Virtual reality technology is the foundation of the virtual manufacturing technology, but at present, the virtual manufacturing technology in our country enterprise applications is still lacking, compared with developed countries, China's enterprises lack the application of virtual manufacturing technology, the production efficiency is relatively low, corporate profits are relatively low, is the result of research of virtual manufacturing technology in our country, the propaganda is not high. Therefore, government departments should take the lead in organizing, organizing related enterprises to carry out research and innovation of virtual manufacturing technology, and strengthening technical exchanges and cooperation with foreign enterprises. Enterprises should, according to their own development needs, constantly improve their production technology to ensure product quality and production efficiency, so as to improve their competitiveness [1].

4. Application of virtual reality technology in manufacturing industry

4.1 Application in clothing design

With the transformation of economic globalization and personalized consumption, the clothing industry began to develop to intelligent manufacturing. With low cost and high efficiency, virtual reality technology plays an important role in the garment industry. The design and display of three-dimensional virtual clothing pursue authenticity and interactivity, bring real look and feel and convenient modification scheme to users, and broaden the imagination space of designers [2].

In the printing process, it is difficult to meet people's needs to finish the design and production of printing and dyeing patterns by hand. In virtual reality technology, the traditional printing and dyeing technology combined with modern printing technology, generate more in line with the people's aesthetic demand design work, under the condition of guarantee the quality of the design and production, maximize the efficiency of production and design, personalized design, and can guarantee security of garment dyeing and printing industry health [3].

4.2 Application in mechanical design

Digital virtual design and verification is the development trend of the machinery industry. In the process of product design and development, the integration of digital design and virtual development technology can realize the whole process of design optimization, performance simulation, verification and evaluation, without the need for physical prototype production and test verification, so as to achieve zero trial production. Compared with traditional manufacturing, it saves labor cost and reduces the dependence on manual operation ability in the design process, greatly reduces material waste, and truly realizes flexible and personalized design [4].

Mechanical design virtual simulation system includes computer equipment, head-mounted or wearable sensing equipment, CAVE projection equipment and other hardware structures, which can be divided into basic layer, interaction layer, data layer and so on. In virtual reality environment, according to the data information of mechanical product structure design, the hardware, such as handheld controller and hybrid motion capture server, establishes a direct dialogue window with virtual assembly environment between users and computer workstations to effectively process the data information of multiple mechanical structures. As for software components, different system development tools are introduced for automatic disassembly and reassembly of various mechanical product parts, which can meet the requirements of multi-person interactive assembly of mechanical products and virtual detection of parts [5].

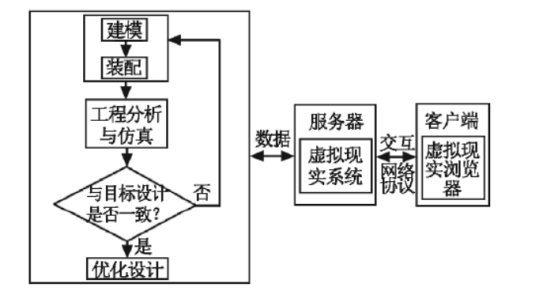

The product is modeled and analyzed by widely used third-party tools such as Solid Works, 3DMAX and PROE, and then exported in a virtual reality file format. In this process, the object of modeling is mainly the main structure and parts of the machine, which mainly shows the interaction between different parts and promotes the complementarity between parts and parts. When the modeling is completed, virtual assembly can be carried out through software to combine the main structure and various parts. In this process, you can directly check whether the parts can meet the production requirements and operational requirements, and this virtual assembly can be completed with the help of the third-party software mentioned above. After the assembly, the dynamics and kinematics simulation analysis of the equipment need to be carried out by mechanical software such as ADAMS, and the finite element analysis of virtual equipment also need to be carried out by software such as ANSYS. These analyses can further improve the simulation quality of virtual equipment and enable it to meet the actual production and operation requirements. After the relevant mechanical properties meet the actual production requirements, the related functions of the system structure need to be tested by software.

After optimization according to the test results, the virtual model can be exported and transferred to the virtual reality browser. Man-machine control can be implemented through the cooperation of software and hardware. The design form of the machine can be viewed directly through the helmet, and the function can be tested through the electronic gloves. If the device allows, it can communicate with the customer directly. The design and related functions of the device can be directly viewed through the Internet and software, which is also the main advantage of improving the efficiency of mechanical design based on the virtual reality system. Through the Internet, multiple subjects can quickly learn about the device design and carry out function testing; Information feedback can provide basis for mechanical optimization (Figure 1). When all performance tests are qualified, the files can be directly transferred to the manufacturer through the Internet for direct manufacturing [6].

FIG. 1 Technical route in virtual manufacturing design

5 conclusion

To sum up, with the continuous optimization and adjustment of current information technology, virtual reality technology has become the main basis for the improvement of social production and life quality. Virtual reality technology, Internet and information technology are integrated to create a cross-space THREE-DIMENSIONAL technology system based on browser, software and hardware equipment, which has a strong application value in the current product design link [6]. Through the optimization of the technical system, the errors existing in the product design can be detected in time, and the targeted adjustments can be implemented, which can promote the rationality of the product design to a certain extent, but also greatly save time and optimize the cost; For related enterprises, it is an important measure to improve production efficiency; For the future development of manufacturing design field, it can describe a blueprint for the development of automation, intelligence and high efficiency.