Quantum Dots in a new Type of display - Dr. Du HANYU

2021-08-02

Abstract: In this paper, the concept of quantum dot (QD) is introduced, and the main display technologies of qD are summarized, including qD backlight (photoluminescence) and QD led (electroluminescence) display. Among them, quantum dot technology for backlight mainly includes quantum dot membrane, quantum dot diffusion plate and quantum dot lens.

I. Concept and principle of quantum dots

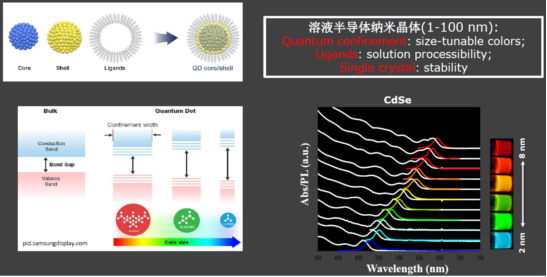

Quantum dots (QDS) are nanoscale solution semiconductor nanocrystals with a size of 1-20nm. By applying an electric or light field to the nanosemiconducting materials, they emit light at a specific frequency. Quantum dots vary in size, so the color of the light they emit can be controlled by adjusting the size of the nanosemiconductor. Figure 1 shows the relationship between the morphology, luminescence principle, luminescence wavelength and size of quantum dots.

Figure 1: Quantum dot morphology, luminescence principle, luminescence wavelength and size relationship.

Quantum dots have the following properties: 1. Emission wavelength/color that can be controlled by size; 2. 2. High saturation emission spectrum; 3. High emission efficiency; 4. High heat/light stability; 5. Wide excitation spectrum and narrow emission spectrum; 5, solution processing. The excellent properties of quantum dot materials enable them to be used in display field.

Two, quantum dot display technology

The application of quantum dots in display technology mainly includes two aspects: quantum dot backlight technology (QD-BLU) based on the photoluminescence characteristics of quantum dots; Quantum dot light-emitting diode display technology (QLED) based on quantum dot electroluminescence. At present, the so-called "quantum dot TV" sold on the market, are equipped with quantum dot film LCD TV, its essence is still LCD TV. At present, quantum dot TV is becoming the mainstream of the market. According to statistics, quantum dot display equipment will be shipped 12 million units in 2020, and the amount of quantum dot material in the next three years will be more than 85 million square meters. These data show that quantum dot technology will become the standard configuration of TV, and China is the base of international display equipment production. The research and development and production of quantum dot materials have great advantages, so the market potential is huge.

(1) Quantum dot backlight technology

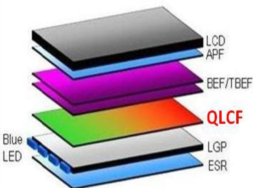

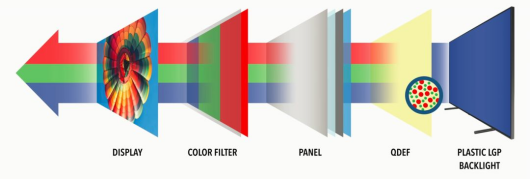

Different from the traditional liquid crystal display, the quantum dot display uses blue LED as the light source. The quantum dot film will excite pure green and red light under the excitation of blue light, and then mix blue light to form high-quality white light. This special nanotechnology realizes the high color gamut coverage of the display, and restores the color. At present, the photoluminescence technology using quantum dot membrane technology is a mature and reliable technology in quantum dot display. Traditional LCD display can achieve excellent color expression ability as long as the white LED light source in the backlight is replaced with blue LED light source and a layer of nanometer quantum dot film is added. Figure 2 is the color comparison diagram of ordinary white LED backlight and quantum dot LED backlight. Figure 3 shows the position and color gamut range of quantum dot film in LCD display.

Figure 2: Schematic diagram of color contrast between ordinary white LED backlight and quantum dot LED backlight.

Figure 3: Position and gamut range of quantum dot film in LCD display.

Quantum dot backlight technology is mainly divided into the earlier tubular quantum dot backlight and the later film quantum dot backlight. The former is mainly produced by QD Vision in the United States, known as Color IQ optical element. The latter is mainly produced by the American company Nanosys and is called QDEF thin films. Nanocrystalline's quantum dots can produce two kinds of quantum-dot backlight components simultaneously. Figure 4 shows the light conversion diagram of quantum dot tube backlight and quantum dot film backlight, as well as the quantum electric film coil.

Figure 4: Schematic diagram of light conversion between quantum dot tube backlight and quantum dot film backlight, and quantum electric film coil.

1. Quantum dot membrane

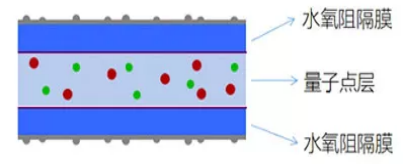

Most QD TVS on the market currently use quantum dot thin films (QDEF). Quantum dot film is a sandwich structure, with two layers of water and oxygen barrier film, and quantum dot polymer film in the middle. The quantum dot film is placed on top of the light guide plate, away from the LED package, allowing the ambient temperature of the QD to drop. Quantum dot film containing QD red and green, the principle for the backlight module in the blue LED blue light, blue light through a quantum dot film, part of the blue light is red dots convert ChengHongGuang, quantum dots into green part of the blue light is green, not converted the blue and green light, red light from the quantum dots of white light together, become a LCD back light. Figure 5 shows the schematic diagram and performance comparison of quantum dot LED, quantum dot tube and quantum dot membrane.

Figure 5: Schematic diagram and performance comparison of quantum dot LED, quantum dot tube and quantum dot membrane.

Quantum dot film is the most mature commercial product of quantum dot display at present, most of the quantum dot TV and display equipment on the market are using quantum dot film. The quantum dot film adopts the "sandwich" structure, and the upper and lower surfaces of the quantum dot layer are covered with water-oxygen barrier film, as shown in Figure 6. Products applied to the liquid crystal display backlight module, placed in the guide plate (or straight down type of diffuser) above, as shown in figure 7, and blue leds can produce combination with sharp peak shape of red, green and blue light, can effectively improve the color gamut of LCD, can be widely used in TV, display, tablets and mobile phones and other end products.

Figure 6: Quantum dot membrane of sandwich structure.

Figure 7: Position of quantum dot film in LCD display.

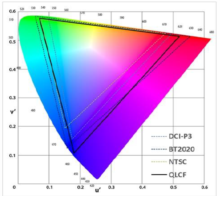

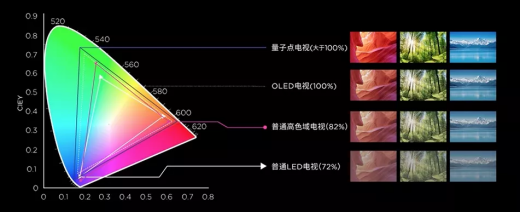

Quantum dot film is the basic principle of backlight module in the blue LED blue light, blue light through a quantum dot film, part of the blue light is quantum dots into green and red light, not converted the blue and green light, red light from the quantum dots of white light together, become the LCD light source, the spectra in red, green and blue three color half peak width is very narrow, as shown in the figure below. The half-peak width of R, G and B colors emitted after filtering is also very narrow, and the single color purity of the display is very high. Figure 8 shows the color gamut comparison of several monitors.

Figure 8: Color gamut comparison of several monitors.

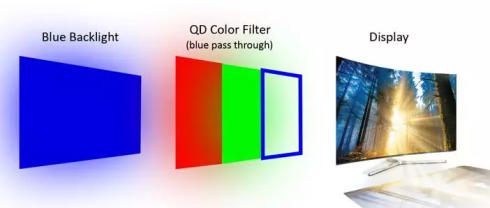

2, quantum dot color filter

One of the most recent developments in the application of quantum dot display is the QD color filter (QDCF), in which quantum dot particles are dispersed in photoresist and then plotted to replace colored dyes in sub-pixels. Each pixel in the quantum dot color filter is composed of three sub-pixel dots, which are respectively ink-jet printed with red quantum dots, green quantum dots and diffused particles. The basic principle is shown in Figure 9. Under the excitation of blue backlight, quantum dot color filter can produce excellent and very high purity primary colors, thus improving the display color gamut. Unlike the traditional color filter model, QDCF acts like an active element, converting light that passes through it rather than blocking it.

Figure 9: Quantum dot color filter display principle

The QDCF approach has the following benefits: a wider viewing Angle because the QDS are placed closer to the screen and they glow in all directions; Wider color gamut, because quantum dots emit pure dimmable light; Thinner display because the QDCF panel has fewer components; And the display is about 50 percent more efficient because quantum dots pass through more light than traditional color filters.

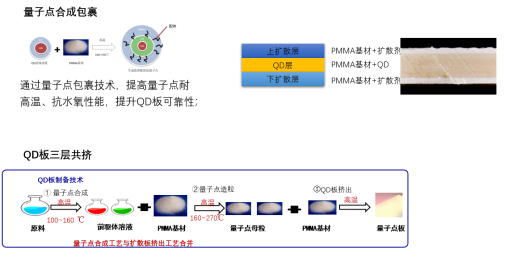

3. Quantum dot diffusion plate

The structure of the quantum dot diffusion plate is shown in Figure 10. The middle layer is the quantum dot layer, and the upper and lower layers are the PMMA substrate plus the diffusion agent layer. The three layers are achieved by co-extrusion. In this process, the quantum dots are first synthesized and wrapped. Through the quantum dot wrapping technology, the high temperature resistance and water oxygen resistance of the quantum dots are improved, and the reliability of the QD plate is improved. TCL Electronics is the first company in the world to use the quantum dot diffusion board, and will use this technology to civilianize the quantum dot technology.

Figure 10: Structure and synthesis process of quantum dot diffusion plate

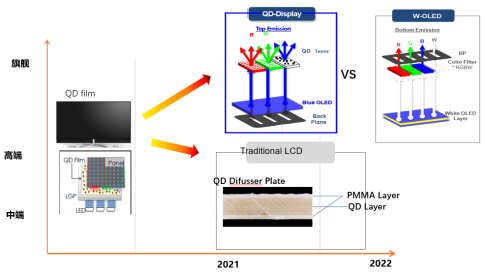

At present, the market to discuss sub-point film application manufacturers are mainly Samsung, TCL, Hisense, Huawei, Xiaomi, quantum dot diffusion board application manufacturers are mainly TCL, Hisense. TCL is the first one in the global TV industry to introduce QD diffusion board technology TV. At present, the quantum dot diffusion plate has the problem of light decline life, which does not meet the requirements in high temperature and high humidity area. Therefore, TCL puts forward the following improvement measures: improving the reliability of quantum dot material, increasing the performance of QD plate to block water and oxygen, and the backlight scheme of standard concentration QD plate. Through the formulation of QD board standardization parameters to achieve the technology to sink to the middle and low end, gradually realize the product standardization. Figure 11 shows the current market usage and the expected future trends.

Figure 11: Current market usage and expected future trends.

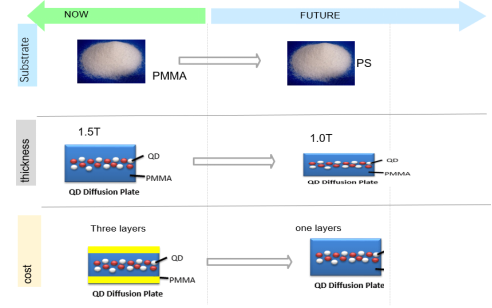

In the future, quantum dot diffusion plates will be developed in the following directions: PMMA substrate will be replaced by PS substrate; The thickness of the diffusion plate will be further reduced; Considering the cost, the upper and lower layers of PMMA will be eliminated and replaced by a layer of quantum dot diffusion plate, as shown in Figure 12.

Figure 12: Future development trend of quantum dot diffusion plates

4. Quantum dot lens

"In the quantum dot backlight mode, QD-LENS scheme will become a trend in the future due to its advantages such as low cost, good light efficiency and easy control. Our current working vision for this product is to expand the spot diameter, refine the lens design and reduce costs to achieve mass production." -- Qiu Xiaohua, Nantong Weiyi New Material Technology Co., LTD. With the popularization of quantum dot display technology, display color reduction has been greatly improved. In order to improve the contrast of THE LCD display, the downward dynamic partition backlight is coming to the fore. Nantong Weiyi Material Technology Co., LTD has developed the quantum dot lens technology based on the downward dynamic backlight, and has made great progress. Figure 13 is a comparison of the structure and performance of backlight modes based on quantum dot membrane, quantum dot diffusion plate and quantum dot lens technology.

Figure 13 is a comparison of the structure and performance of backlight modes based on quantum dot membrane, quantum dot diffusion plate and quantum dot lens technology.

In general, now the membrane material from the machine design, cost control has been widely recognized, and the use of maturity is higher, so in a quite long period of time intima or the main technical route; The diffusion plate shows great advantages in reliability and stability, and will make good progress in large size. While microlens also has its own advantages, it needs to solve the industry pain points and a certain amount of time for end customers to be familiar with and accept.

(2) Quantum dot led display technology

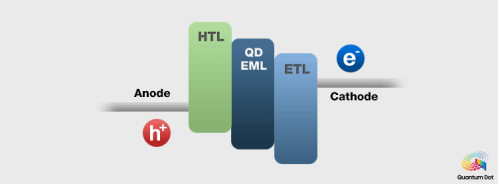

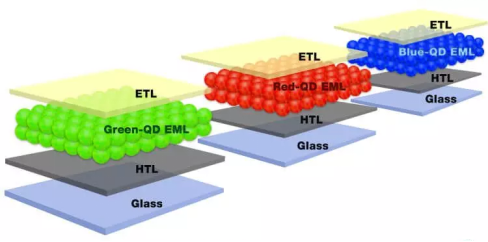

The quantum dot led display technology is an electroluminescence technology. The principle is that the quantum dot layer is placed between the electron transport and hole transport organic material layer, and the applied electric field makes the electrons and holes move to the quantum dot layer, where the electrons and holes are captured to the quantum dot layer and recombined to emit photons, as shown in Figure 14. By encapsulating red quantum dots, green quantum dots and blue fluorescent body in a diode, the white light is emitted directly. When this electroluminescence mechanism is employed, the quantum dot material is placed between the anode and cathode, and each sub-pixel contains red, green and blue QDS, as shown in Figure 15.

Figure 14: Luminescence principle of quantum dot led display technology

Figure 15: Schematic diagram of three-color quantum dots encapsulated in a diode

This approach offers a number of benefits: a very wide color gamut, since quantum dots emit light in a narrow spectrum and can be well tuned; High contrast, because each pixel can be controlled independently; High brightness at low power consumption; No backlight, no liquid crystal layer, no color filter; Ultra high resolution; It will not burn the screen because it is not made of organic material; Design flexibility, since there is no backlight, this mechanism allows the technology to be used for flexible, foldable, crimp and transparent displays; Cheaper to manufacture than OLED, QD patterning uses ink-jet printing equipment rather than expensive and slow evaporation equipment.

According to the IHS analysis, shipments of flat panel displays are expected to exceed 250 million square meters by 2025, with TFT-LCD still dominating the market, but OLED has some penetration in medium to small sizes and large sizes. This is mainly due to the advantages of electroluminescence technology, such as no backlight, higher efficiency, more energy saving, and thinner size. Compared with OLED, QLED also belongs to the field of electroluminescence technology. The advantage of quantum dots is that they can be freely adjusted in the size of nanometers to achieve full band display. Meanwhile, the luminescence spectrum of quantum dots is very narrow, the display is very pure and the color gamut is wider. QLED ushered in a real explosive development, every year there are breakthroughs in related technologies in China, such as TCL, BOE have some layout research work.

According to the distribution of display products, different application scenarios have different requirements for display size and resolution. For small size, the resolution is higher, while for large size, the resolution is lower. As mentioned earlier, quantum dots are nanocrystals of semiconductors, and its printing technology has become a very good process route for quantum dot display technology. Through printing technology, the utilization rate of materials can reach 100%, so there are certain advantages in cost.

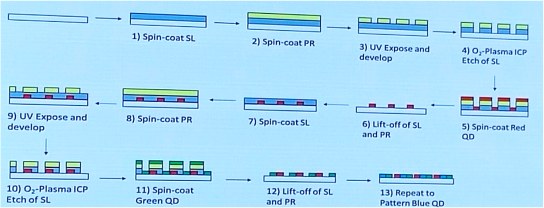

Currently QLED electroluminescent display technology is mainly used mobile phone port of medium and small size, the cost of a small and medium size itself is higher, so we also hope to QLED have some application in small and medium size in the future, but in small and medium size requirements in terms of resolution is higher, so we came up with some other methods, How to achieve high resolution QLED. You are most likely to think of is lithography process, the current lithography process is now institutes of universities, enterprises and the attention of industry, quantum dots as ligands on the surface of the semiconductor nanocrystals of quantum dots, lithography process can achieve quantum dots: some through light can be decomposed ligands and quantum dot surface to cooperate, endowed with the function of the quantum dot a lithography. Mixing quantum dots and photoresist directly is a method to realize the photography of quantum dots. This method is characterized by a relatively simple process, but it has some disadvantages, that is, in the process of development, quantum dots are not easy to remove, easy to remain and produce color mixing. Boe Display has developed a new process called sacrificial layer Assisted lithography, as shown in Figure 16. This lithography process solves the problem of color mixing and difficulty in elution by introducing a sacrificial layer. Using the sacrificial layer assist method, a 500PPI full-color pattern was achieved, equivalent to a 16-inch 8K resolution level.

Figure 16: Quantum dot sacrificial layer assisted lithography process developed by BOE

At present, in the process of the development of QLED device technology, there are mainly the following problems: First, there is a lack of cadmium-free materials, and qLED-matched transmission materials are also scarce; Secondly, the development of ink-jet printing ink. In terms of devices, the luminescence mechanism of quantum dots is not very clear, because the structure of devices is relatively complex, so it is necessary to strengthen the QLED fundamental research, and make a huge improvement in the efficiency of QLED from the fundamental level.

Comparison of photoluminescence and electroluminescence of quantum dots

From the essence of the product, photoluminescence application is mainly in the film or plate; From the perspective of device structure, electroluminescence is more complex than photoluminescence. Because photoluminescence is relatively mature and develops rapidly, the application of electroluminescence is limited by the lack of materials, which will lead to the limitation of the thickness and weight of display products and the application of flexible display. At present, it is mainly limited to blue light materials. The efficiency and equipment of red and green electroluminescence have basically reached the commercial level, while the efficiency and equipment of blue light are still relatively low. The application of quantum dot electroluminescence technology is still not perfect, the main application is inkjet printing technology, but it also has the printer positioning accuracy, ink development stability and other problems. Therefore, at present, the application of quantum dots is still polarized luminescence, electroluminescence requires joint efforts.