Application and Development strategy of Maglev Holography in high-speed train - Qian Li, Ph.D

2021-11-11

By the end of the first half of 2021, China had 146,000 kilometers of railways in operation, including 38,000 kilometers of high-speed railways. A safe and efficient railway network with reasonable layout, extensive coverage, well-structured structure, and smooth circulation of the national economy has been basically completed, providing railway transport infrastructure guarantee for the construction of a modern distribution system and smooth circulation of the national economy. At the same time, organized by CRRC and led by CRRC Sifang Co., LTD., more than 30 domestic universities, research institutes and enterprises in the field of maglev and high-speed rail have jointly developed a 600km/h high-speed maglev transportation system. The project was launched in October 2016, and the test sample vehicle was developed in 2019, and successfully ran on the test line of Tongji University in Shanghai in June 2020. After system optimization, the final technical scheme was determined, and the complete system was developed in January 2021 and the six-month joint adjustment and joint test began.

Based on the working principle of middle-low speed maglev train with electromagnetic levitation, the technical characteristics of each core subsystem (suspension guidance system, traction motor, walking mechanism, braking system, rail-bridge structure, etc.) of middle-low speed maglev are described. The development history and technical characteristics of Linimo train from Japan, EcoBee train from Korea, Changsha Maglev Express Line, Beijing Maglev S1 line and the (suspended) mid-mounted maglev train independently developed by Southwest Jiaotong University are summarized.

Holography is used to improve the redundancy design of low and medium speed maglev. Maglev wheel-rail flow should be distinguished from subway wheel-rail flow, the coupling characteristics of maglev train should be fully considered, and the engineering practicability of seamless power supply rail technology in low and medium speed maglev should be explored. The accuracy and stability of the control algorithm and the fault diagnosis technology of the suspension system should be improved because of the low dominant frequency of the controller and the long running cycle of the program. In order to improve the carrying capacity of medium and low speed maglev train, the structural characteristics of the vehicle body and the traveling mechanism should be considered in the lightweight design of the train on the basis of ensuring the structural strength. The requirements of different maglev lines should be integrated, and unified line standards should be established to improve the engineering application ability of medium and low speed maglev lines.

Maglev train has no direct mechanical contact with the track, is not limited by the traditional wheel-rail adhesion limit, and has the advantages of low vibration and noise, smooth operation, small turning radius, strong climbing ability, etc., which has received attention and continuous research in many countries. At present, Japan's East Hill Line (TKL line), Korea's Incheon Airport Line, China's Changsha Maglev Airport line and Beijing maglev S1 line have realized commercial operation. Maglev trains can be divided into electro-magnetic Suspension (EMS), electro-dynamic Suspension (EDS), high temperature superconducting Suspension and electromagnetic - permanent magnet hybrid Suspension according to the Suspension principle. According to the speed grade can be divided into low speed, medium speed, high speed, super high speed and space speed maglev.

At present, medium and low speed maglev trains are all EMS models, which are drawn by short stator linear induction motor and generally run on elevated Bridges. Medium and low speed MAGlev trains do not have the traditional wheel-rail contact, but instead use the non-adhesive magnetic interaction between electromagnet and track, which requires active control to maintain stable suspension clearance. Of the low-speed maglev train research is mainly to provide support, guide and traction/braking solutions, make the operation of the train has a good stability, stability, security and curve through sex, its unique technology solutions derived relations, such as magnetic - rail suspension control, train - control - line coupling vibration, etc. New research category.

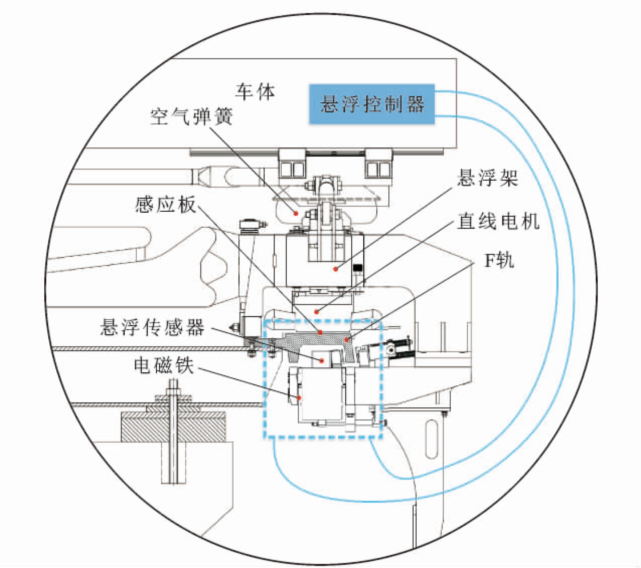

The suspension and guidance system structure of medium-low speed maglev train is shown in Figure 1. The electromagnet fixed on the suspension frame and f-shaped ferromagnetic track attract each other to realize suspension and guidance functions.

FIG. 1 Section of suspension and guidance system of medium-low speed maglev train

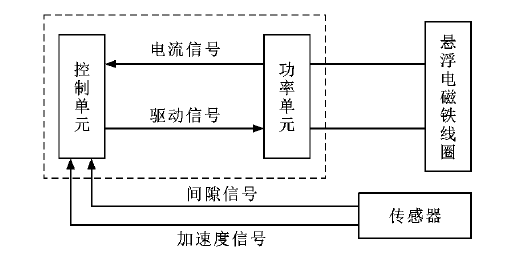

Holography is also suitable for maglev systems. This is because the electromagnetic levitation force is inversely proportional to the square of the suspension gap. The open-loop electromagnetic levitation system is unstable, and feedback control must be introduced to keep the suspension stability. The suspension system of the medium-low speed maglev train feeds back the signal of the suspension sensor, and the suspension controller adjusts the current of the solenoid coil in real time to keep the suspension gap within the dynamic stable range (usually 8-12mm). The suspension sensor is integrated with a clearance sensor and an acceleration sensor. The clearance sensor monitors the relative clearance between the electromagnet and the F rail, and the acceleration sensor measures the absolute vibration acceleration of the suspension electromagnet. The suspension sensor monitors and feeds back the real-time signal to the suspension controller, which is processed by the control algorithm to adjust the excitation current of the suspension electromagnet, so as to achieve a stable suspension control.

The suspension controller consists of a control unit and a power unit. The function of the control unit is to realize the signal receiving and filtering of the levitation sensor, levitation control algorithm and power unit control signal generation. The power unit directly provides electric energy for the electromagnet, which is essentially a chopper. The driving signal transmitted by the control unit is generally PWM signal containing duty ratio information, and the power unit carries out controlled current-changing output to drive the electromagnet to generate and adjust the suspension magnetic field in real time, so as to maintain the stable suspension of maglev train. The signal flow of the suspension control system is shown in Figure 2.

FIG. 2 Signal flow of suspension control system

The necessity of developing high speed maglev in China is mainly reflected in four aspects: (1) Implementing the development strategy of transportation power and promoting the construction of transportation power. At present, the transport infrastructure in general realized from the beginning of reform and opening to the outside of the "bottleneck" to the end of the 20th century "preliminary relief", and then to the need to "basic adaptation" economic and social development across the stage, but compared to meet people's growing demand for a better life, compared with the advanced world level, there is still a gap between the traffic development in our country. To this end, the CENTRAL Committee of the COMMUNIST Party of China and The State Council issued the Outline for The Construction of a Transport Power, which clearly proposed the "construction of 123 travel traffic circles nationwide" and "reasonable planning and arrangement of 600 KMPH high-speed maglev system technology reserve research and development". China should give full play to our country in the high-speed maglev line, Shanghai and occurring in the process of construction of low-speed maglev technology, the construction technology and operating experience into productivity, and break through a number of cutting-edge led technology, modern engineering technology and disruptive technology, efforts to achieve the key core technology independent controllable, pushing up transportation to the value chain, We will help build China into a transport powerhouse.

② Enrich the comprehensive transportation system to meet the needs of passengers. China has a vast territory, about 5,500 km long from north to south and 5,200 km wide from east to west, forming major urban agglomerations such as The Beijing-Tianjin-Hebei Region, the Yangtze River Delta, Guangdong, Hong Kong and Macao, Chengdu-Chongqing, and the middle reaches of the Yangtze River. The distance between the urban agglomerations is more than 1,000 km. China has established a transportation system based on aviation and high-speed rail, but there are still two problems: (1) there is a speed gap between aviation and high-speed rail. Wheel-rail system is affected by energy consumption, line ride and bow network relationship, so it is difficult to further improve the speed. ② The travel time between major urban agglomerations is too long. In the north-south direction, the travel time between Beijing and Shenzhen is about 8 hours by high-speed rail and 5.5 hours by plane (including waiting time, not including connection). In the east-west direction, the travel time between Chengdu and Shanghai is about 11 hours by high-speed rail and 5 hours by plane, which is beyond reasonable comfort. (3) Drive the development of related industries and promote the upgrading of industrial structure. In the process of China's national economic construction, major projects drive industrial reform

New, it has achieved successful practice in the Qinghai-Tibet Railway, the Hong Kong-Zhuhai-Macao Bridge and the high-speed railway. A complete industrial chain will be formed around the planning, design, construction, operation and management of high speed maglev

Consulting (consulting, planning, survey and survey, design), raw materials (infrastructure supporting, building materials); The middle reaches include construction (engineering machinery, civil construction, mechanical and electrical installation), equipment manufacturing (mechanical equipment, electrical equipment, intelligent system); Downstream includes operation and maintenance (resource management, driving organization, passenger transportation organization, crew organization, safety monitoring, maintenance management, emergency management), application (public utilities, transportation services), value-added services (business, training, engineering services), etc. In addition, in the process of high-speed maglev industrialization, it will drive the development of a series of related industries such as equipment manufacturing, metallurgy, chemical industry, electric power and building materials, promote industrial technological innovation and the development of emerging industries, and promote the upgrading of China's industrial structure. (4) The need to promote regional integration and participate in global competition. Urban agglomeration or urban belt is an important carrier to drive regional industrial agglomeration and promote regional integrated development, as well as an important link for a country to participate in global competition. On the basis of the existing transportation system, Japan's East Pacific Coastal Urban belt has planned to build the central Shinkansen, and construct the "one-hour" transportation circle of three metropolitan areas, so as to increase communication among metropolitan areas, promote regional revitalization and enhance international competitiveness. In contrast, China has already planned the Beijing-Tianjin-Hebei urban agglomeration, Yangtze River Delta urban agglomeration, Guangdong-Hong Kong-Macao Greater Bay Area and chengdu-Chongqing double-city economic circle. It is necessary to plan high-speed maglev within and between urban agglomerations to shorten travel time, promote regional integrated development and enhance global competitiveness.

The development of high speed maglev in China is to implement the development strategy of a transport power and promote the construction of a transport power, to enrich the comprehensive transport system and meet the needs of passengers, to drive the development of relevant industries and promote the upgrading of industrial structure, to promote regional integration and participate in global competition. Comprehensive consideration of national development strategy, economic development level, passenger transport demand, existing and planned transport system and other factors, the development strategy of high-speed maglev is proposed. In the near future, the Beijing-Shanghai-Hangzhou Channel and the Beijing-Guangzhou Channel and the southern section of Changsha have carried out the construction of the Grand Trunk Line. Long-term planning of beijing-Guangzhou channel changsha to the north, southeast coastal channel and along the river channel, the final construction of "bow type" high-speed maglev network, the formation of "3 hours" traffic circle.

In 2019, It was proposed in The Outline of Building China into a Transport Power that China should make reasonable arrangements for the r&d of 600 km-per-hour high-speed maglev system, 400 km-per-hour high-speed wheel-rail (including variable gauge) passenger train system, and low-vacuum tube (tunnel) high-speed train. Although the wheel/rail train top operational speed is still a world difficult problem hasn't been cracked, but can insight is that more than 600 km per hour must adopt maglev technology, realize from the wheel/rail to the maglev transition, this will be China and the world railway traffic region second disruptive technology innovation, and is also a human track traffic history into the only way for the high-speed era. Normal conductor magnetic levitation, low temperature superconducting magnetic levitation and high temperature superconducting magnetic levitation have their own advantages and disadvantages, and their application prospects are analyzed as follows.

(1)400-600km• H-1, as the speed connection between high-speed rail (300km• H-1) and aviation (600km• H-1), can not only supplement the capacity shortage in important corridors, but also provide differentiated services. It can form a more reasonable, efficient, flexible and convenient multi-dimensional traffic architecture of aviation, wheel-rail high-speed rail, high-speed maglev and urban traffic speed gradient, to meet the travel needs of different groups. This velocity domain can be used with normal or superconducting magnetic levitation technology. Changdao and low temperature superconducting electric maglev transportation engineering technology has been mature, the research and development in recent years mainly focuses on reducing cost, environmental friendliness, improving efficiency and safety. On June 21, 2020, the 600km• H-1 high-speed magnetic levitation test sample, developed by CRRC Sifang Co., LTD., ran on the Magnetic levitation test line of Tongji University, becoming a successful attempt to break through the technical speed bottleneck of normal conducting electromagnetic levitation.

(2) 600-1000km• H-1, no matter wheel-rail or maglev, must be equipped with low-pressure pipelines, otherwise it is difficult to solve the problem of excessive aerodynamic resistance and noise. After adding low pressure pipe, the cost will certainly increase greatly, and the cost of the long stator required by high speed maglev will also increase. However, limiting the speed to 600km•h-1 is uneconomical. Currently, the maximum operating speed of the normal magnetic levitation system cannot exceed 600km•h-1. Based on the above technical and economic analysis of the normal magnetic levitation, the superconducting magnetic levitation technology is a choice in the speed range of 600-1000km• H-1.

(3) Special lines of 1000km• H-1 and above should be built between big cities to give full play to the advantages of low operation cost, short operation cycle, noise-free and pollution-free, and stations that can be built in downtown areas, so as to further relieve the pressure of civil aviation transportation. High temperature superconducting maglev and low temperature superconducting electric maglev have been proved to exceed the speed of 1000km• H-1 in principle. Therefore, high temperature superconducting and vacuum pipeline or electric maglev and vacuum pipeline maglev transportation technology can be used. At speeds above 400km• H-1, more than 83% of traction is wasted in offsetting air resistance. The researchers hope to reduce air resistance to maglev trains by creating a vacuum tube environment. Under the low vacuum environment, the HTS maglev track needs to lay permanent magnet materials to form magnetic tracks. Although the relative cost of track construction increases, it can effectively drive the development of rare earth resources in China.

Taken together, China's original HTS maglev relies on a unique pinning action to suspend or suspend, and can run along a permanent magnet track to achieve self-suspension, self-stability and self-guidance. Operating speeds can reach 600-1000km• H-1 or higher. In terms of comprehensive technology and reliability, China's high temperature superconducting magnetic levitation technology can be used above 600km• H-1, which has the advantage of late development and epoch-making significance. The development of high speed and ultra-high speed maglev rail transit system need special support, Ministry of Science and Technology research and development of the national key project gathers the domestic high-speed rail, maglev field advantage resources, joint companies, universities and research institutes jointly tackling key problems, conquer high-speed maglev core technology, developed with independent intellectual property rights of more than 600 km, h - 1 and high-speed maglev engineering system, Gradually form the industrialization capacity of China's high speed maglev. At present, Chinese research institutions are making continuous efforts to carry out research in accordance with engineering objectives.

In fact, in the speed range of 200-400km• H-1, maglev train has no competitive advantage compared with wheel-rail train, that is, "wheel-rail world"; The speed above 600km• H-1 must adopt low-pressure vacuum pipeline magnetic levitation technology, which has great space for speed increase. The application of magnetic levitation holographic technology to high-speed train has broad prospects, which is also one direction of our efforts, which is the "maglev future".