Introduction of HOLOGRAPHIC Waveguide technology of HMD based on AR--Li weina

2020-10-02

1 Background introduction

Augmented Reality (AR)/Mixed reality (MR) technology is the next generation of virtual reality (VR) technology, as well as the development direction of 3D display. AR system pays more attention to interaction than VR system [1]. Usually, AR systems contain electronic and optical equipment such as microcomputers, projectors, microphones, speakers, and input/output couplers, so it is necessary to make them smaller and lighter.

[2] In the 1990s, HITLAB produced the ARToolKit. The AR game "ARQuake" was introduced in 2000. Wikitude AR Travel navigation for Android mobile devices was released in 2008. In 2013, Google released a Beta version of Google Glass, an AR device that includes a microcomputer, camera, projector, tiny liquid crystal display (LCD), cell phone, and speaker. It can also connect to the Internet and other devices via wireless networks and Bluetooth. These include email, maps and photos, videos, phone calls, and Internet connections. In 2014, Sony released SmartEyeGlass, a wearable glass-type 85% holographic AR device that also includes the usual features of other AR devices, but the holographic guide structure is the holographic guide for the system, so it's small in size and lightweight. In 2016, Niantic Labs released "Pokemon Go", an AR based mobile game, which became the most popular mobile game in a short time, attracting more attention to AR technology. In 2017, Apple Inc. announced support for AR data in their new operating system, and in the same year, Microsoft showed a prototype of a holographic near-eye display, a perspective system that USES holographic waveguides. Google glasses, Epson's Moverio, SONY's SmartEyeglass, Vuzix's see-through AR smart glass, and Microsoft's hololens all use optical waveguide structure, as shown in figure 1, because the optical waveguide structure makes the AR system smaller and lighter.

(a)

(b)

(c)

(d)

(e)

Figure 1. Products of today's AR waveguide HMD

(a) Glass Enterprise Edition 2 (from Google) [Source: https://www.google.com/glass/tech-specs/]

(b) SmartEyeglass sed-E1 (from Sony)

[Source: https://developer.sony.com/develop/smarteyeglass-sed-e1/]

c) Vuzix Blade (from Vuzix) [Source: https://www.vuzix.com/products/blade-smart-glasses]

(d) MOVERIO BT - 35 e (the from Epson) [Source: https://tech.moverio.epson.com/en/bt-35e/]

(e) HoloLense 2 (from Microsoft)

[Source:https://www.microsoft.com/en-us/p/holoLens-2/91pnzzznzwcp/?activetab=pivot%3aoverviewtab]

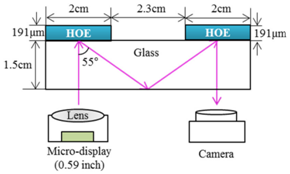

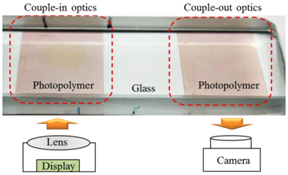

Introduction to full color holographic waveguides

In this article, we briefly introduce the HEAD-mounted display (HMD) holographic waveguide technology based on AR. Typically, the holographic waveguide is composed of a holographic optical element (HOE) and a glass, as shown in Figure 1 [3], where the two HOE films are used as input and output couplers respectively, and the glass is used to transmit light (image signals) between the two couplers. HOE film is mainly made of photopolymer. Type according to the reconstruction can be divided into reflection the HOE (reflection type and transmission type (transmission - type), the transmission type HOE is in the process of reconstruction through the volume holographic grating (holographic volume gratings and HVGs) decoupled into image signal, and reflective HOE through HVGs reflecting a particular wavelength band, the image signal transmission area to another direction, HVGs is a record by laser interference in the light of polymer. Therefore, the see-through AR display system works better with a reflected HOE.

Figure 1. Schematic diagram of the holographic waveguide

First, the diffraction efficiency of the holographic waveguide should be analyzed, that is, the ratio of the optical energy diffracted into the waveguide to the total optical energy received. In general, the higher the diffraction efficiency is, the higher the image quality observed by human eyes will be. Therefore, the diffraction efficiency of HOE in the holographic waveguide structure directly affects the quality of the final real image. Therefore, it is necessary to accurately measure and calculate the diffraction efficiency, that is, to measure the HVG diffraction efficiency recorded on HOE.

Photopolymer has been used as an in-Coupler and out-coupler in reference [3]. A brief introduction to the optical properties of Photopolymer is given as it is considered to be the best HOE material for holographic waveguide applications with perspective AR display. To display a full color image on the holographic waveguide AR display, the HVGs recorded with red, green, and blue lasers will all be recorded on the HOE film, but not simultaneously, otherwise the diffraction efficiency will be very low. The diffraction efficiency can be as high as 97% if only one of the lasers is used, as shown in Figure 2 (C-E).

(a)

(b)

(c)

(d)

(e)

Figure 2 (a) HMD system with polychromatic HOE; (b) Input image (white); (c) The output image of a single red laser HVG; (d) HVG output image of a single green laser; (e) Output image of blue laser HVG.

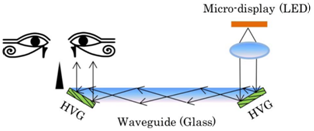

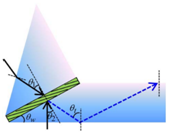

When it comes to getting a full color display, however, HOE's composition must address both the thickness of the holographic waveguide, its weight, the uniformity of its color display, and the fact that its field of view is too small. The wedge-shaped holographic waveguide expands the field of view with a highly diffracted HOE and improves the uniformity of the color display. By placing the input and output couplers at a specific Angle, the thickness of the waveguide is reduced by a large Angle of total reflection and, because HVGs can choose a wider Angle, the field of view is enlarged, as shown in Figure 3:

(a)

(b)

FIG. 3 (a) Schematic diagram of a wedge HOE holographic waveguide, and (b) schematic diagram of the Angle of the waveguide optical path

Piao et al. [4] measured the diffraction efficiency of a single HOE using three full-color lasers (red =633nm, green =532nm, and blue =473nm) to record HVGs three times. For example, red-green-blue means that HVG is first recorded with a red laser on the photopolymer, then with a green laser on the same Photopolymer, and finally with a blue laser on the same Photopolymer, and finally the diffraction efficiency of the full-color HVGs on each of the three lasers is measured. Six sequential measurements were made, including red-green-blue, red-blue-green, green-red-blue, green-blue-red, blue-red-green, and blue-green-red. The optimal sequence was green-blue-red, with diffraction efficiencies of 49%, 47%, and 44%, respectively. Because this sequential recording shows higher optical efficiency and more uniform distribution, and has the potential to obtain high-quality images. As shown in Figure 4, it can be observed that the green-blue-red laser sequence shows the highest color uniformity and uniformity.

(a)

(b)

(c)

(d)

(e)

(f)

FIG. 4 Experimental results of the wedge waveguide, (a) input image (white); (c) The output image of a single red laser HVG; (d) HVG output image of a separate green laser; (e) HVG output image of a separate blue laser; (f) Full-color HVGs output images using green-blue-red recording sequences

Although HMD using optical waveguide technology has the advantages of small size, easy to carry, and a good grasp of the Angle and spectrum sensitivity, etc., the AR type HMD of optical waveguide currently in the market is still not cheap, usually three or four thousand yuan, and the general public still cannot afford it. Moreover, the diffraction efficiency of the optical waveguide system with full color display is still very low, and still needs to be improved.

reference

[1] Authoritative Guidance on Augmented Reality (AR) technology; Authors: Takeshi Zita, Qingchuan Qing, Longshi Okuma

[2] Wikipedia. Head-up Display. 2009. Available from:

https://en.wikipedia.org/wiki/Headup_display

[3] J.-A. Piao, G. Li, M.-L. Piao,N. Kim, Full color holographic optical element fabrication for waveguide-type head mounted display using photopolymer. Journal of the Optical Society of Korea. 2013; From cuthah 2-248

[4] M.-L. Piao, N. Kim, Achieving high levels of color uniformity and optical efficiency for a wedge-shaped waveguide head-mounted display using a photopolymer. Applied Optics. 2014; 53:21. 80-2186